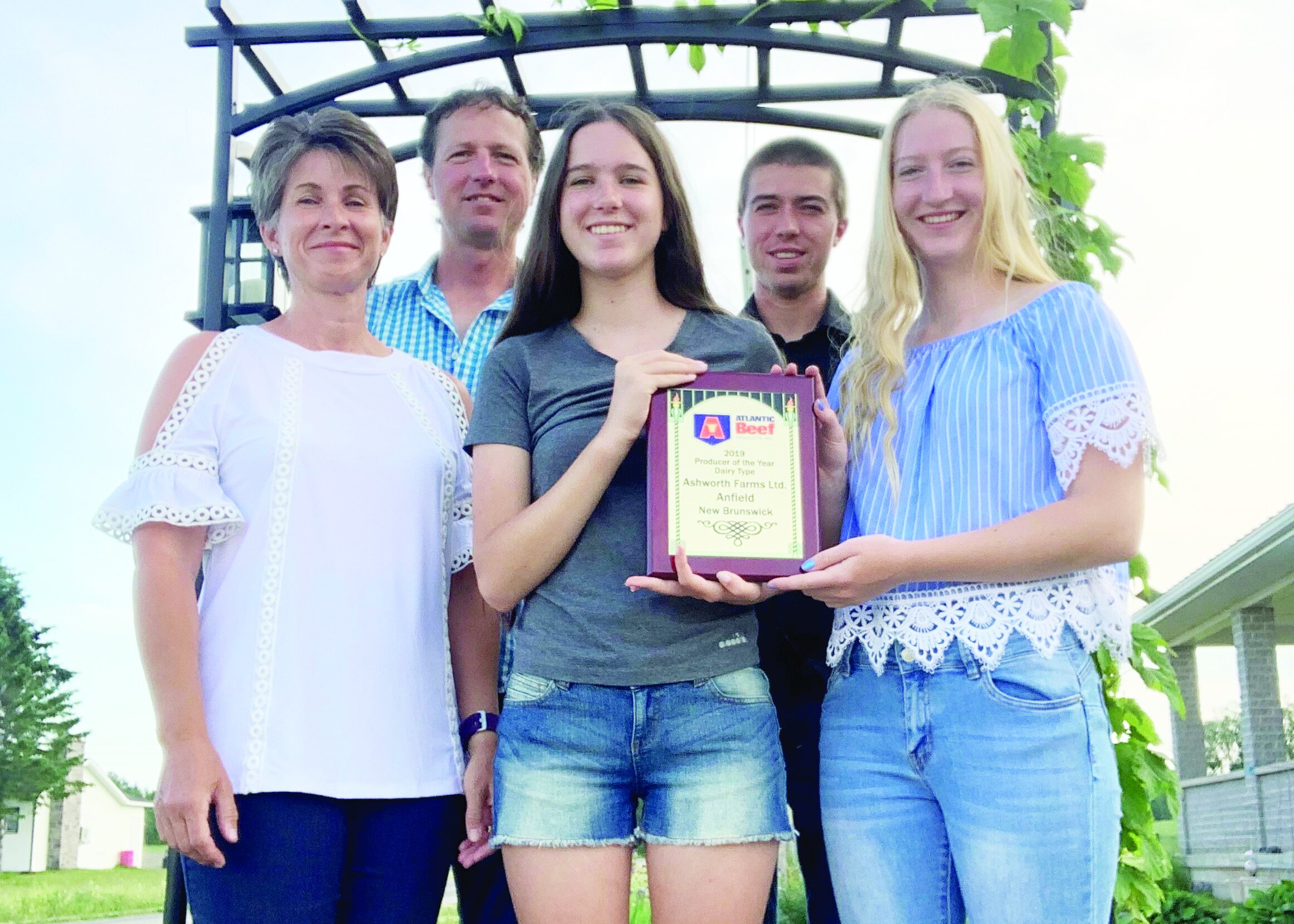

AANB president and her family operate a dynamic dairy farm

/by George Fullerton

Lisa Ashworth graciously agreed to a profile of her farm on very short notice in mid-July. But, as president of the Agricultural Alliance of New Brunswick (AANB), she was participating in a Canadian Federation of Agriculture (CFA) conference call. And her husband Derek and their son Logan were busy baling hay. So my guides to Ashworth Farms would be daughters Grace and Anna.

As the farm visit began, it took only a few minutes to be impressed with their in-depth knowledge of just about every aspect of the family’s 320-cow milking operation.

In 1908, John and Tamer Ashworth emigrated from England and landed in Anfield, N.B., about 20 kilometres south of Grand Falls, where they established a mixed farm. In 1960, two of their grandsons, brothers Cecil and Neville Ashworth (Derek’s father), bought the farm, which had 60 cleared acres and 20 milking cows.

Grace said that buying and clearing land was an obsession for the early generations of her family. That generational effort resulted in 1,500 farmable acres and 200 acres of pasture.

In 1987, when the Ashworths moved their cows from a tie-stall barn to a free-stall barn, they were milking 160 cows.

Derek attended the former Nova Scotia Agricultural College (NSAC) in Truro from 1993-97, graduating with an animal science degree. At the NSAC, he met Lisa, who accumulated an animal science degree and a master of science degree at that institution before adding a bachelor of education degree from Mount Allison University in Sackville, N.B. They were married in 1999 after their post-secondary education was completed.

In 2000, Derek and Lisa bought out Uncle Cecil’s share of the farm, which had expanded to a milking herd of 220. In June 2000, they suffered a fire that resulted in the loss of a good deal of equipment and three major buildings, but thankfully their herd was saved.

Grace will start her second year of the international food business program at Dalhousie University’s Agricultural Campus (the former NSAC) in the autumn and hopes that COVID-19 restrictions will have relaxed enough to allow her to study and intern at Aeres University of Applied Sciences in the Netherlands. The international food business program is a joint venture between Dalhousie University and Aeres University. Dal AC students who are enrolled in the program spend their second year studying at Aeres University, followed by a European internship.

Anna will start high school in Grand Falls in the fall. Logan completed a two-year dairy program at Dal AC.

LOTS OF FORAGE

The Ashworths have a good forage crop this year. With about 1,000 acres in production to feed the entire herd – which is close to 1,000 head – it makes one wonder how they get the forage cut and in the bunkers at the prime stage of growth.

The prime question was: What’s used for mowing?

“We have two sets of three Kverneland mowers,” said Grace, adding that the mowers are 10-feet wide, with one ahead of and two trailing each tractor. “I have been mowing for several years and Anna started mowing this year with the second set of mowers. Some days get pretty long in the tractor, and we learn to eat our lunch on the straight stretches.”

Grace outlined the mowing training program.

“Dad got in the cab the first day and talked to me as I made the first cut around the field,” she recalled. “And then he said, ‘You know, it will be easier if I get out now and you work away at it.’ At first, I was quite nervous but very soon I realized he was correct, and I got pretty comfortable with it. I mow with a 6210 John Deere, and we run it at about 12 kilometres per hour.”

She added, “Dad packs the bunkers and he will call me to ask how far ahead of the merger and the chopper I am. Sometimes that puts some pressure on if they are catching up to me.”

Logan operates a 30-foot Oxbo pull-type forage merger ahead of a self-propelled chopper and four tandem silage trucks.

MILKING REGIME

The first point of interest on the tour was the massive 30,000-litre milk tank on the way to see the crew well into their 3:30 p.m. milking. A three-person crew milks using a 28-cow rotary parlour. Udders are washed and pre-dipped with an automatic brush apparatus. A second crew member applies the milker claws. As the carousel turns, the milker claws automatically drop off and a third crew member post-dips each cow prior to exiting the carousel.

“Before we got the pre-dip brush, we used cloths to wash and dry every udder,” said Grace. “There were these huge tubs of cloths, and the washer and dryer were running nearly around the clock. The pre-dip brush works great and is very efficient.”

Each milking takes a little more than two hours to complete.

The milking cows are on a slated floor and their free stalls have rubber mats and are bedded with planer shavings.

The milking cows are fed TMR (total mixed ration) and they also have free-choice access to dry hay.

This year’s big forage crop has necessitated the construction of two new bunker silos to handle corn silage, bringing the bunker inventory to nine.

In 2017, a new barn was built to house dry cows and maternity pens as well as to facilitate heifer raising. The new barn is connected to the dairy barn by a tunnel to allow for safe and controlled movement of the cattle.

“The cows seem to really like the tunnel and it makes moving the cows simple and relatively easy and no worries about slipping on ice,” said Grace.

GROWING CALVES

Newborn calves move into individual stalls and are tagged and fed colostrum for several days. Next, they move into group pens and feed from a computerized milk replacer feeder that provides small volumes several times through the day. Additionally, calves have free-choice access to a grower concentrate. As the calves grow, they’re moved through a series of pens, eventually into a free-stall-style pen.

As the heifers mature, they’re fed TMR and hay. Mature heifers have access to pasture in season.

Derek explained that they’re continually adapting their breeding program to try to best fit the herd for today and the future. Most of the milk cows are bred with conventional beef genetics, while the majority of the heifers are bred with sexed Holstein semen. He added that this breeding strategy allows the farm to capitalize on genetic potential.

The majority of their land is planted to a forage mix and corn, and is adjacent to the farmstead. But the Ashworths also have 150 acres of fields that are a 30-to-40-minute tractor drive away in an area called Sadler Flats. The fields are on rich alluvial soil lying between the Tobique River and forested highlands. The Sadler land came to the Ashworth farm through Grace’s late paternal grandmother Molly (Sadler) Ashworth.

It was eventually time to visit the farmhouse and thank Lisa for the farm visit. It was a pleasant surprise to see her mother, Betty Lou Scott, sitting in the kitchen. Scott of Mount Thom, N.S., has been an Angus breeder and cheerleader of note. She continues to be a vocal cheerleader for Angus, her community, and all things agriculture. She pointed out that this was her only trip outside of Nova Scotia in a year because of COVID-19 regulations.

It was a remarkable kitchen visit with three generations of dedicated farm leaders.

MULTI-TASKING

Lisa apologized for not being able to join the farm tour, gave a brief review of the CFA meeting, prepared the family’s evening meal, and discussed the possibility of a federal election, agriculture policy, and lots more.

In addition to her AANB work, Lisa handles the farm’s administrative tasks, including updates to their environmental farm plan and the proAction program, payroll, and much more, not to mention maintaining a spotless kitchen and offering visitors fresh baking.

Ashworth Farms has about 10 employees in addition to the immediate family members.

Derek noted that his cousin Andrew Ashworth (Uncle Cecil’s son) is a key component of the farm’s success. Andrew handles equipment maintenance, service, and repair, and does all the silage chopping.

“Staff is the most important aspect of any business and cannot be overlooked for farming,” said Derek. “Without the dedication of a team of employees, we would not be able to find any success or enjoyment out of the agriculture industry. Our current staff is an amazing group of hard workers who show up at all hours to get the job done.”

Derek’s father Neville, who’s in his early 80s, is still the main man for picking up parts and supplies for the farm. Derek added that his father “continues to be a great wealth of knowledge and is wonderful for continually supporting and helping the entire crew to get things done.”